PRODUCTS

DRY FLOWABEL (DF)

DRY FLOWABEL (DF)

SC formulation becomes DF

There is a big difference between DF and WDG process. It is whether we need make SC formulation firstly. SC is sprayed from the top of the tower then meets the adjuvant to become granules (DF)

Better physic performance

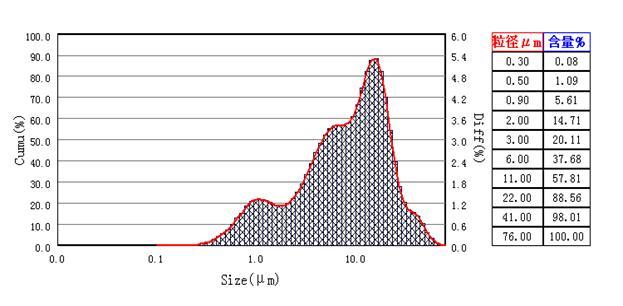

Smaller particle size than WDG leads to better disintegration

|

ITEM |

VALUE |

REMARK |

|

|

WDG |

DF |

||

|

A.I.,%,m/m, |

-- |

-- |

HPLC |

|

Suspensibility,%,m/m, ≥ |

70.0 |

85 |

HPLC |

|

Wetting time S, ≤ |

60 |

30 |

CIPAC MT53.3 |

|

Collapsing time S, ≤ |

120 |

30 |

CIPAC MT53.3 |

|

Particle Size,um |

10 |

3 |

D50 |

|

43 |

10 |

D98 |

|

|

100 |

15 |

D100 |

|

|

Dispersing,%,m/m, ≥ |

70 |

85 |

CIPAC MT174 |

|

Dust, %, m/m,≤ |

0.5 |

0.5 |

CIPAC MT171 |

|

Density,g/L |

480~530 |

400~500 |

CIPAC MT58.3 |

|

Persistent Foam, ml,≤ |

25 |

25 |

CIPAC MT47.2 |

|

Moisture, %, m/m, ≤ |

3.0 |

3.0 |

CIPAC MT30.1 |

|

Appearance |

Off white D1mm |

Off white |

|

Appearance

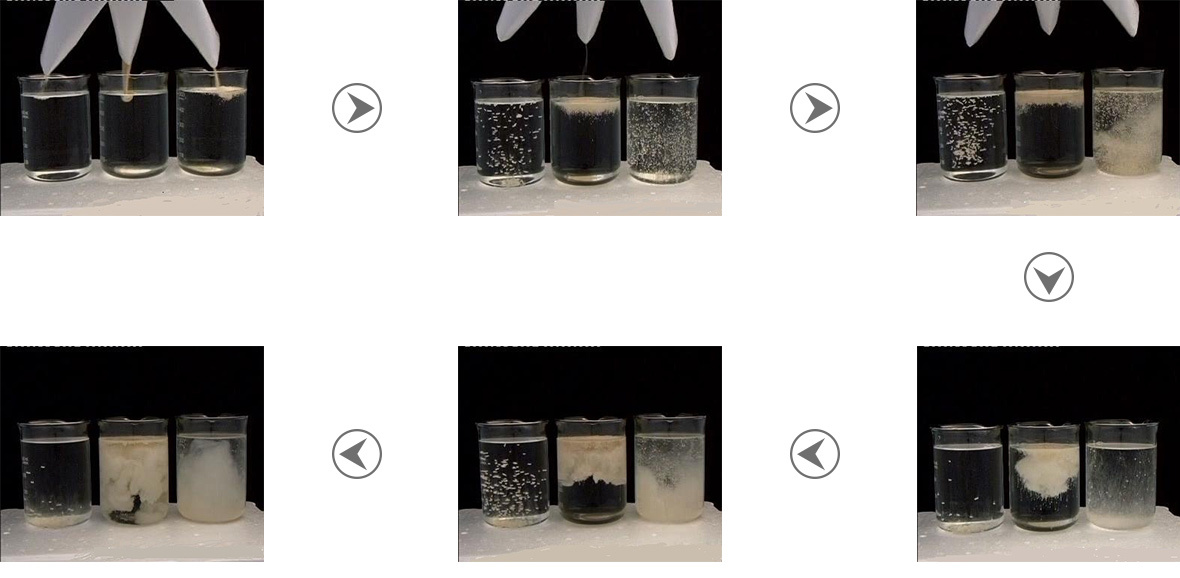

Collapsing Compare between compaction WG (left), DF (middle) and fluid-bed WDG (right)

|

|

| Distribution curve of DF Particle Size | Distribution curve of WDG Particle Size |

previous

next

previous

next

LANGUAGE

LANGUAGE